Our Product Promise

Explore our wide range of lifting solutions, carefully selected to meet your needs reliably and efficiently. Whether you need overhead crane systems, hoists, or jib cranes, we have the perfect product to fit your requirements.

Product Overview

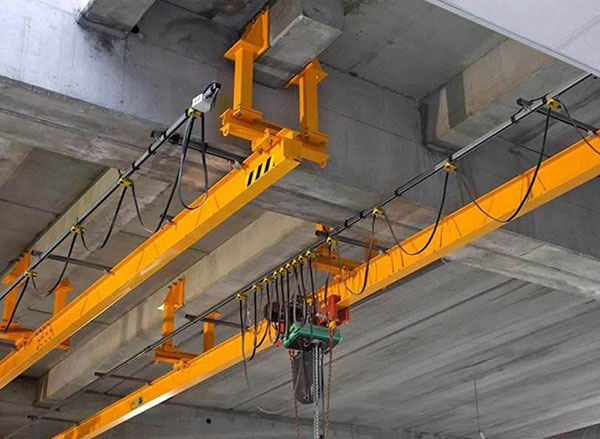

Bridge Crane

Features a movable bridge that travels along a set of parallel rails mounted on either the walls or elevated columns of the workspace. This crane consists of a hoisting mechanism, which is typically a wire rope hoist or chain hoist, mounted on a trolley that can move across the bridge, allowing it to access wide areas across the facility.

Gantry Cranes

Gantry cranes come in three distinct forms, full gantry crane, semi gantry crane and portable gantry crane.

Runway Structures

An overhead crane runway structure is an integral part of an overhead crane system. It consists of a set of parallel tracks or beams on which the crane moves. These tracks are typically mounted on supporting beams or girders, which are in turn supported by columns or the building structure itself. The runway allows the crane’s bridge, which carries the hoisting mechanism, to travel longitudinally along the workspace, providing coverage of a wide area. The design and construction of the runway structure are critical for the safe and efficient operation of the crane. It must be robust enough to support the weight of the crane and the loads it carries, as well as withstand the forces generated during lifting and moving operations. The alignment and level of the runway are also crucial to ensure smooth and reliable crane movement. This structure can be found in various industrial environments, such as manufacturing plants, warehouses, and shipyards, where heavy or bulky materials need to be moved regularly across large areas.

Jib Cranes

A jib crane is a type of crane that features a horizontal jib or boom, which is an arm that extends horizontally from the crane’s mast or vertical support. This jib supports a moveable hoist fixed to either a trolley or directly on the jib, which can move along the jib’s length. Jib cranes are typically mounted on a wall or floor and can rotate, offering a wide range of motion. The jib’s rotation angle can vary, with some cranes offering up to 360 degrees of movement, making them highly versatile for lifting and moving loads in a circular area around the crane’s base. They are widely used in industrial and manufacturing settings, workshops, and warehouses, particularly in areas that are too small for larger cranes or where quick and frequent lifting is needed. Jib cranes are ideal for localised lifting tasks and can handle loads ranging from very light to several tons, depending on their design and construction.

Workstation Crane

A trussed track workstation crane is a type of overhead crane system designed to facilitate material handling in a specific, confined area, typically within a workstation or between multiple workstations in a facility. This crane features a trussed track, which is essentially a piece of track that has been reinforced with a truss structure to increase its strength and rigidity, allowing it to span longer distances without sagging or bending under heavy loads.

The trussed track structure makes the crane more lightweight compared to solid beam or girder designs, while still providing high load capacity and stability. The crane’s hoist and trolley system run along this track, enabling precise and smooth movement of goods horizontally along the track’s length. A workstation crane is the most ergonomic crane solution you can purchase, meant for repetitive lifting that requires precision placement. These systems can be motorized or driven manually, and come in ceiling mounted, floor mounted or monorail configurations.

Monorails

A monorail crane is a type of overhead crane that consists of a single beam configuration, allowing the hoist to move in a straight or curved path. The monorail beam is typically attached to the ceiling or supported by columns within the facility. The hoist, which is mounted on a trolley, runs along the monorail beam to lift, and transport materials along the predetermined path.

Monorail cranes are ideal for processes that require linear movement of materials across areas where extensive lateral movement is not necessary. They are commonly used in production lines, assembly operations, and other applications where space is limited, and specific routes need to be followed regularly. This type of crane is particularly effective in streamlining workflows and increasing efficiency in environments with a high volume of repetitive movements.

Hoists

Fall Arrest Systems

Safety and security are paramount when working at heights. Our Metreel Safe-Track Fall Arrest Systems are designed to provide maximum protection and ease of use. These systems are engineered to prevent falls and ensure the safety of your workers, offering peace of mind and compliance with safety regulations.